Sunday 29 December

I have now 3 weeks off work so some progress should be very possible.

Since last post I have hosted a gathering of the AEVA Adelaide members at my home for a Saturday BBQ & general "Gasbagging" about things EV-wise. About 22 attended which was a pretty good rollup. Not to waste the occasion I obtained a number of handy suggestions , though these wont be visible, they are useful in the wiring up situation.

This shows the positive HT feed now with lugs to attach to the emergency switch ( that's it top right of picture) mounted in the centre console

You can see that the glove box is still out , and so is the rest of the dash. I have yet to mount an LED that will feed from EVBMS from Ian Hooper in WA. Plus I am still perplexed over wiring into the heater fan circuit as part of the fail-safe measures for the demister. So that is why the glove box is still out, as it covers the wiring etc. for the fan motor.

Here is the console with the emergency switch and provision for the JLD404AH Intelligent Meter.

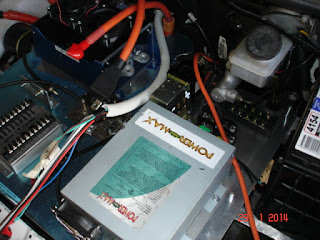

The two shots above are looking at the mounting box for the circuit breaker switch on left side of the grey box ( which will eventually have a cover). To the right is the 144v battery charger.

The feeds that pass out to the underside of the car can be seen, as can the mounting bolts that hold down the battery frame. These mount directly onto the seat belt mounts and ought to provide conformation to Aust. design standards for mounts.

The grey box also contains the 75mv shunt for the JLD404AH meter. The additional fuse is for 144v Neg. feed back to the meter as well.

Underside of car looking forward.

Mounting all 45 batteries in the frame . Used SS banding in 3 sets of 15 batteries.

Then, also there is a 25mm flat passing between the banks terminating on a 1/4"thread. That then passes through part of the frame , to additionally lock in the banks. Finally there are 8 hold-downs on top that will be the final method of locking in the banks into the frame.

Progress with mounting the electrical hardware. Still mind bending!!!!!!

Progress also with the BMS wiring and battery interconnectors.

.jpg)